How wood stoves work, how emissions are measured, and how Regency minimizes our environmental impact.

There is lots of misinformation and even more outdated information about wood stoves out there. Municipalities, local clean air groups, and other parties have expressed concerns over wood burning products going so far as to ban new wood products or lobbying to remove rebate and other subsidy programs that are designed to replace old inefficient units with today’s highly efficient wood models.

This article will provide a brief overview of the government’s emission standards, the main concern with wood burning products, and how modern technology meets the clean-air standards set forward by the Environmental Protection Agency (EPA) and other governing bodies.

Government Standards - Emissions

Government Standards - Emissions

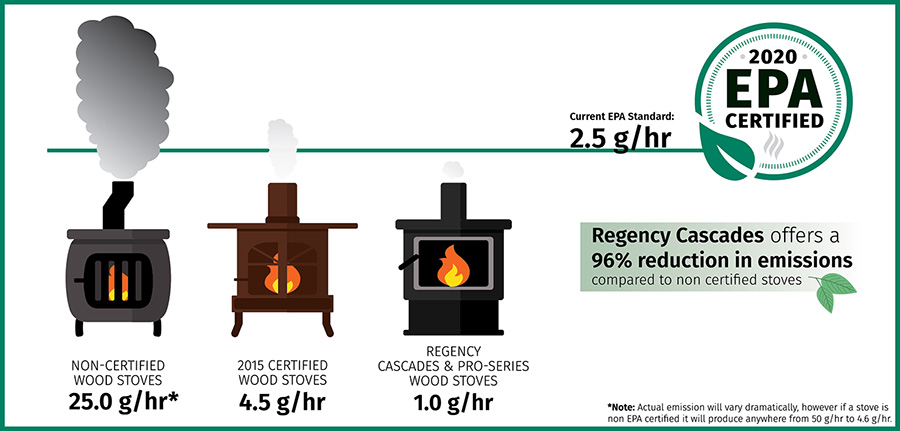

EPA 2020 Guidelines require all wood burning products to produce less than 2.5 g/hr in particulate matter. In 2015 the previous guidelines required less than 4.5 g/hr in particulate matter to be released by wood burning stoves.[i] The 2020 guidelines dramatically reduce the amount of particulate matter that is released by today’s stoves. Regency Cascades series not only meet but exceed EPA guidelines and have been certified at 1.0 g/hr.

Fine Particulate Matter (PM 2.5)

The primary concern for anti-wood activists, aside from greenhouse gas emissions, is the release of microscopic particulate matter that measures less than 2.5 microns (μm) – which is approximately one-thirtieth the size of a single strand of human hair. These particulates can lodge themselves inside your lungs and cause respiratory problems with prolonged exposure or high concentrations.

Modern wood burning technology is specifically designed to reduce this particulate matter through a process that involves multiple combustion reactions that utilize gasses and particulate matter as fuel for secondary and tertiary burns. The result is significantly reduced levels of particulate matter that are below the World Health Organizations guidelines.[II]

According to a report released by the EPA on reducing residential wood smoke…

“CHANGING OUT ONE OLD, DIRTY, INEFFICIENT WOOD STOVE IS EQUIVALENT TO THE PM 2.5 POLLUTION REDUCTION OF TAKING FIVE OLD DIESEL BUSES OFF THE ROAD.”[III]

How Modern Wood Stoves Stack Up

Modern Wood Burning Technology – How It Works

Modern wood burning stoves contain decades of advancements that allow them to burn cleaner, for longer, while using less wood. Typically there are two designs that allow a wood stove to meet emissions standards – Catalytic and Non-Catalytic. To not only meet but exceed regulations Regency has created a third category – a Hybrid wood stove.

Catalytic Stoves (Two-Stage)

A catalytic stove uses a catalytic combustor to superheat particulate matter as it passes through it; burning off the majority of the particulate matter and gasses while generating more heat than the original combustion reaction. A catalytic combustor is a honeycomb-like structure that heats up to temperatures greater than that of the fire and as the gasses are exposed to the higher temperatures and undergo combustion.

Non-Catalytic Stoves (Two-Stage)

A non-catalytic stove that meets emission guidelines will typically use air tubes to help re-burn the gasses and reduce emissions to an acceptable level. As a result of the initial combustion reaction gasses and particulates are released within the firebox. While the fire burns air is circulated, superheated and fed through air tubes inside the firebox, as they are released at the top of the firebox they mix with the gasses from the initial combustion and ignite, undergoing a secondary combustion which burns off the additional gasses and particulate matter.

Hybrid Stoves (Three-Stage)

Hybrid wood stoves are the cleanest and most efficient wood stoves on the market. These stoves use a combination of non-catalytic and catalytic stove technology to create very efficient and clean burns that reduce very limited emissions.

Stage one is the normal combustion reaction that occurs as the wood burns. The second stage occurs when the superheated air is mixed with the gasses from the initial combustion and then re-ignited, removing a large portion of the gasses and particulate matter. Lastly, in the third stage any remaining gasses and particulate matter from stage two are funneled through the catalytic combustor where the particulates and gasses are superheated and burned for a third time further reducing the remaining emissions to a level that is well-below government standards.

Efficiency

Not only does modern technology help reduce the amount of particulate matter, but it also reduces the total amount of wood required to be burned, further reducing its environmental imp act. With Regency’s hybrid stoves offering up to 50% longer burn times, homeowners are able to reduce the total amount of wood they need to burn throughout the heating months.

By re-burning particulates the stove is able to utilize both the wood and trapped gasses as fuel, meaning more of the available energy in each log is utilized. Traditional open fireplaces can utilize around 20-30% of the available energy in a piece of wood whereas todays modern stoves can utilize up to 87%.

Regency Cascades Series (2020 EPA Certified)

The Regency Cascades Series are hyper-efficient wood burning stoves and inserts that produce 1.0 g/hr of particulate matter. That is a 98% reduction compared to an open wood burning fireplace (50.0 g/hr) and a 78% reduction compared to previous EPA standards (4.5 g/hr).

What makes the Cascades series so different is the use of triple-stage Eco-Boost technology. This process burns the wood, gasses, and particulate matter not once, not twice, but three times. By undergoing three separate combustion reactions the stove is able to remove 98% of particulate matter and gasses as a result of burning.

.aspx)